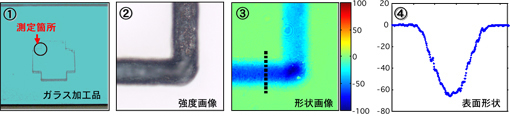

Shape of the sample surface can be measured.

Groove processing on the surface of the transparent glass can be done by ablation phenomena that are occurred when it is focused on the surface of the glass board with femtosecond laser.

Fig 2-1 We observed glass artifact with optical microscope.

Fig 2-2 As we look at the intensity image with the microscope, it is focused on the vertical groove and indistinct on the horizontal groove.

This is speculated that the depths of the vertical and horizontal grooves are different.

Next, we demonstrate measuring result of the surface shape with QPM in Fig 2-3.

In this way, we can measure quantitatively that the depths of the vertical and horizontal grooves are different.

Fig 2-4 shows that the plotting of the shape of the dot-line in fig 2-3.

QPM can measure the surface shape of the sample. It can contribute to find the optimum processing condition for the processing shape that you needed and improve the production of processed goods.

Fig.2 Glass surface processing and surface shape measurement with femtosecond laser.